Maxwell MRS-7/350 Primary Foam Filled Seal (IFR Rim Seal)

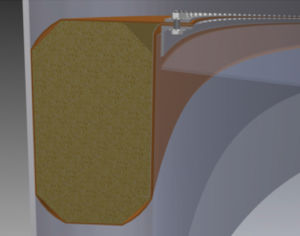

Our MRS-7/350 Primary Foam Filled Seal, is a resilient foam-filled rim seal, which acts like a liquid-filled seal except that a resilient foam log is used in place of the liquid. The resiliency of the foam log permits the seal to adapt itself to minor imperfections in tank dimensions and in the tank shell. The foam log can be mounted above the liquid surface (vapor-mounted) or on the liquid surface (liquid-mounted).

Resilient foam-filled seals work because of the expansion and contraction of a resilient material to maintain contact with the tank shell while accommodating varying annular rim space widths. These seals consist of a core of open-cell foam encapsulated in a coated fabric. The elasticity of the foam core pushes the fabric into contact with the tank shell. The seals are attached to a mounting on the deck perimeter and are continuous around the roof circumference.

Polyurethane-coated nylon fabric and polyurethane foam are commonly used materials. For emission control, it is important that the mounting and radial seal joints be vapor-tight and that the seal be in substantial contact with the tank shell.

The most commonly used Maxwell Liquid Mounted Seals either normally used in a combined configuration are:

• MRS-7/350 Primary Foam Filled Seal

All Maxwell IFR Rim Seals can be combined with;

• MRS-70 Secondary Wiper Seal

Finally, when the local requirements are pushing local terminals or refineries to add a tertiare or tertiary or triple rim seal, on request these extra rim seals can be provided by Maxwell.