Maxwell Swivel Joints & Swing Joints (Oil Skimmer Systems)

The Maxwell Floating Suction and Skimmer Lines is an internal piping assembly that allows operators to withdrawal product from the upper levels of the medium stored in their storage tank.

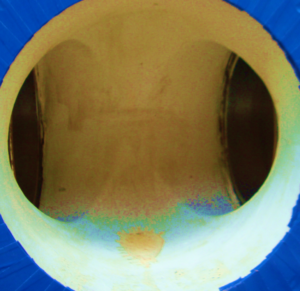

Maxwell oil skimmer systems are a proven solution for draining a light liquid product from the top of a heavier product in a cone or dome roof storage tank. The Skimmer floats on the top product (ex. oil over water) to collect the lighter of two non-mixable liquids into a vortex funnel. The liquid is then drained out of the tank through oil skimmer lines using rigid articulated pipe (having one or more joints) are designed to travel in a vertical plane and prevent damage to the floating roof and the skimmer line through its design range of travel.

Draining the light fluid is controlled by using a valve at the shell nozzle. (Small) Pumps can also be used to draw off the light fluid out of the tank.

The intake is adjustable during installation. The Maxwell Oil Skimmer Systems are engineered using information from the customer supplied data sheet.

During installation the Maxwell oil skimmer systems can be adapted for use in internal floating roof tanks as well as external floating roof tanks. In this instance, instead of using pontoons to float on the liquid, the Maxwell oil skimmers are attached to the roof to keep the intake to the roof distance constant.

The Maxwell Oil Skimmer Lines are available in standard sizes from 3” up to 24”. All our joints will be delivered with a test certificate.

Engineering details of the articulated piping equipped with Swivel Joints (Offset) & Swing Joints (Central) are provided upon request.

Models

The most commonly used Maxwell articulated pipe oil skimmer joints systems are:

• Flexible Hose Joints

• Swivel Joint (Offset) & Swing Joint (Central)